Miscentering during wheel balancing procedures is the number one cause of improper balancing and customer comebacks. Automatic CenteringCheck® always monitors wheel centering to reduce setup errors.

Hunter HD Elite™ Wheel Balancer

Eliminate wheel-related vibrations in heavy-duty assemblies

Hunter HD Elite™

HD Elite™ wheel balancer at-a-glance

Measure runout and balance faster than any traditional balancer

Eliminate error opportunities with the patented laser vision system

Solve vibration problems by detecting and matching the high spot of the tire using the diagnostic load roller

Ensure proper centering with patented automatic CenteringCheck®

Maximize efficiency using SmartWeight® technology

True self-calibration with patented eCal auto-calibration

Wheel lift assists up to 500-lb. assemblies and provides proper mounting

Service car and light-truck assemblies as well

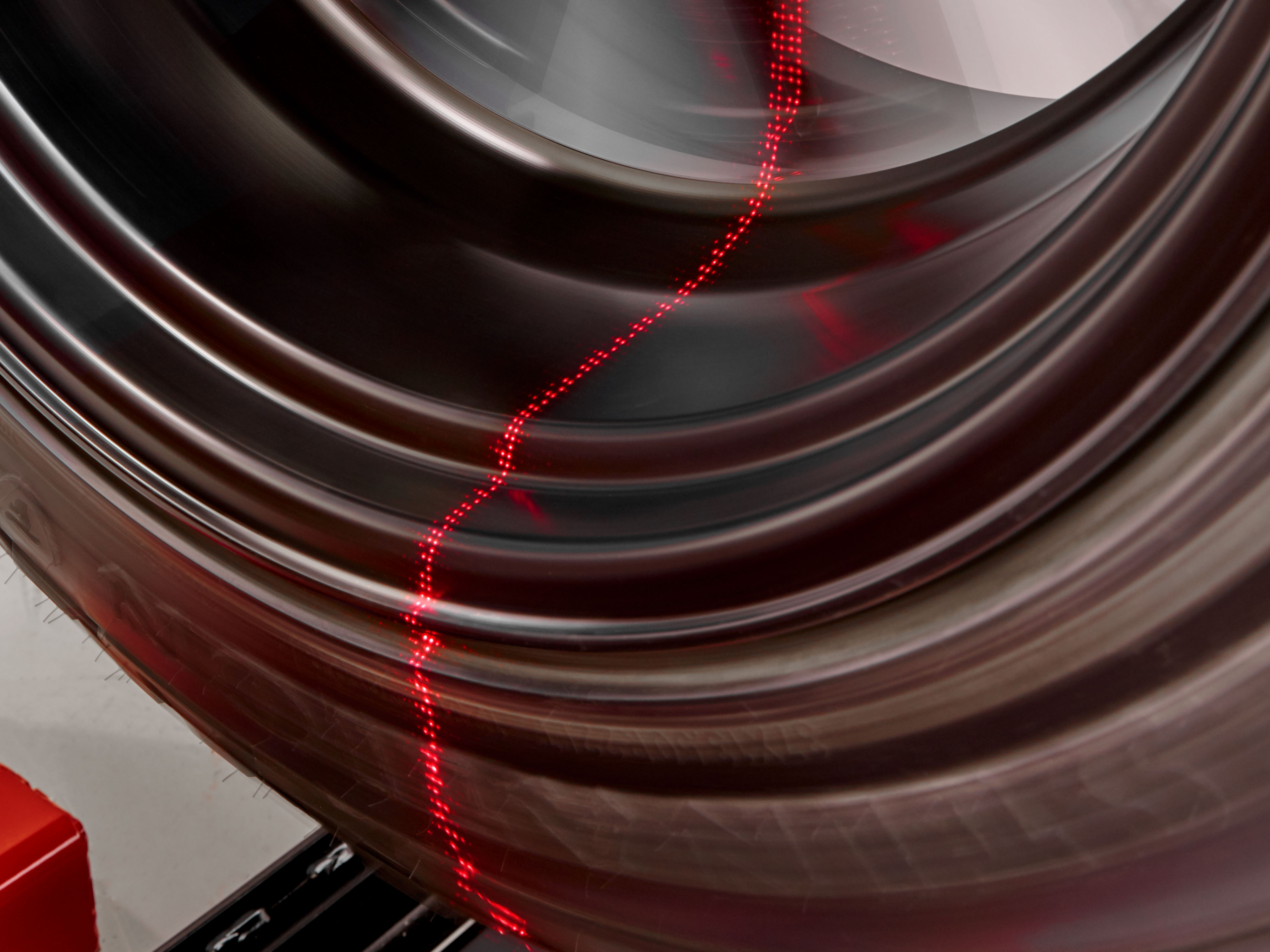

Laser vision system

Patented vision technology provides more benefits in less time

Automatically determines weight plane locations

Selects clip or tape weight usage

Calculates ForceMatch® solution

Creates a three-dimensional model of the rim

Allows more single-weight solutions

Prioritizes hiding tape weights behind spokes

Automatic features reduce effort and errors

- Eliminate manual dimension entry and runout measurement

- Automatically select weight mode

- Hide wheel weights through patented algorithms

NEW Smartspot® weight placement pinpoints the exact tape weight location. This removes any confusion and saves time by reducing weight chasing, or repeated trial and error.

Touchscreen interface

Powerful controls and real-time 3D graphics at your fingertips

- One-touch to display rim dimensions

- Rim cutaway displays selected weight mode

- Switch text language with the push of a button

- TruWeight™ provides live navigation through selection and placement of wheel weights

- ForceMatch® panel displays assembly runout value and limits

Automatic CenteringCheck®

ForceMatch® prediction

Simple graphics illustrate how to optimize assembly. Live, color-coded graphics show the technician force variations.

Assembly diameter display

Easily accessible to make matching dual assemblies a snap.

High spot display

Mount dual assembly high spots 180 degrees apart to increase tire life.

On-board videos

Video tutorials help technicians better understand features and functions.

Send a message to your local Hunter business consultant to receive a free pricing quote or product demo.

Uh-oh. That isn't supposed to happen.

We are currently experiencing issues with our ROI calculators. Please come back later while we fix it.

HeavyDuty Elite ROI

Boost your returns with ForceMatch

Turn ForceMatch into a new profit center and service all assemblies to avoid comebacks

Make Forcematch a profit center

Advertise your vibration diagnostics service to attract new customers.

Solving 2 new customers vibrations per month @ $120 per session, could generate:

$2,106 Gross annual profit (30% labor & parts)

Forcematch every assembly and avoid comebacks

Comebacks are inconvenient to your customers, take time away from your service techs and could cost your business $1,800 in opportunity cost annually.

1 Comeback per Month x 1.5 Hours to diagnose and fix x $100 Shop Rate

$150 Opportunity cost monthly

Customer satisfaction

Eliminate wheel-related vibration for a smooth ride by matching the tire to the wheel assembly

1. An unknown force vibrates the spindle

The customer notices strong vehicle vibrations. Vibration is transferred from the wheel through the steering column to the driver.

2. Specialized sensors measure the assembly

The HD Elite™ wheel balancer automatically measures runout (eccentricity) of a tire and wheel assembly. The roller measures the entire contact patch of the tire, detecting if the assembly is out-of-round.

3. Match-mounting cancels the vibration

Match-mounting the high spot on a tire to the low spot on a rim makes the assembly roll as smoothly as possible. Runout-related vibration is minimized, ensuring your customer a smoother ride and longer tire life.

Match dual assemblies to maximize tire life

Opposing high spots

Dual tire assemblies with aligned high spots (1) behave like single assemblies with runout. Marking and installing wheels with high spots 180 degrees opposed (2) makes the dual assembly more round than the two assemblies alone and reduces vibration.

Unequal load on duals

Mismatched diameters on dual tires causes the larger tire (2) to carry more load, thus generating more heat and reducing tire life. The lesser diameter tire (1) may develop premature tire wear due to slippage relative to the road surface.

Revolutions per mile

Dual tire assemblies with mismatched diameters cause the smaller tire (1) to turn faster and thus be dragged along with the larger tire (2). For example, if one tire has just 1/8-in. less tread depth than the other, it will be dragged 33.3 feet per mile traveled.

Get noticed

Improve your visibility and credibility by letting customers easily find your shop based on their location.

- Search completed by ZIP code

- Refine search by distance within miles from location

Cancel vibrations by match-mounting!

When combined with one of Hunter's heavy-duty tire changers, the HD Elite™ provides match-mounting capability for achieving the smoothest possible ride.

Efficiency & innovation

Save time & money with exclusive features

Single-weight solutions

SmartWeight® technology determines optimal weight placement to avoid excessive use and save money.

View your savings

Track your weight usage savings on-screen.

Any wheel size

Never turn down a customer. Service car and light truck wheel assemblies as well.

Touchscreen interface

Intuitive, easy-to-learn controls

Wheel lift

Easily lift wheel assemblies up to 500 lbs. and ensure a proper mount.

HammerHead® system

Optional

Top-dead-center laser system assists in easy weight placement.

Accessories stand

Standard

Adaptor tree conveniently stores oversized balancer accessories.

See how you can provide a smooth, over-the-road ride for your customers.

HunterNet® 2 Portal

Take control of your equipment, numbers, and profitability

Real-time business tool to manage your most profitable equipment

- Maximize your shop's performance

- Monitor your equipment ROI

- Buy genuine Hunter consumables

Learn more about what HunterNet® 2 does for other Hunter equipment

Receive automatic, daily reports

- Automatic daily snapshots in addition to a 7-day overview of performance trends

- View inspection rates and opportunities

- Measure alignment numbers and conversions

- Track balancing and ForceMatch® utilization

Specifications

|

|

|||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Your local Hunter service representative can answer questions, help with equipment operation and provide on-site training.

Purchase genuine Hunter replacement parts online

This contact form is intended for legitimate Hunter equipment and service inquiries. All other use is prohibited and will be discarded. See Full Terms of Use

Take a closer look at other satisfied users

Documents

-

Brochures

-

Specification Sheets

-

Accessories

Hunter's 3-Year Warranty

We stand beside our equipment and your purchase.

Hunter Engineering Company warrants new equipment replacement parts for three years and labor for six months.

Explore further

WinAlign® HD Alignment

Multi-axle truck alignmentsReduce setup times and see live measurements on three axles on multi-axle trucks using self-centering, cordless sensors.

Hunter service

Largest in the industryHunter deploys the largest service force of highly-qualified representatives in the industry.

Hunter Training

ASE-CertifiedLearn from knowledgable trainers in hands-on equipment usage and classroom learning.